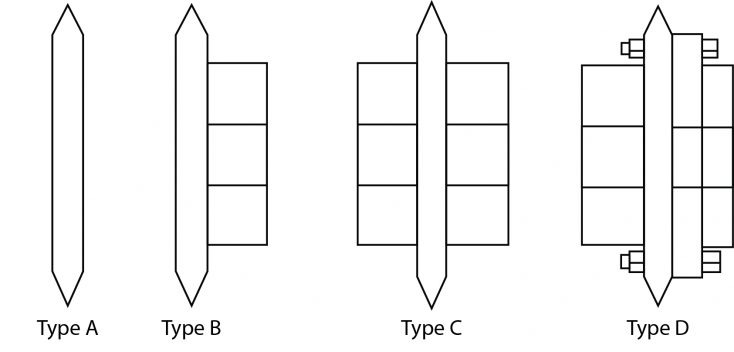

Types of sprocket

A sprocket is a wheel with teeth, cogs, or even sprockets that mesh with the holes in the links of chain, track, or other perforated material. A sprocket is different from a Gear because a sprocket never meshes directly with another sprocket. Sprockets are designed to be used with a specific chain. Choosing the right sprocket optimizes sprocket/chain interaction, ensures drive performance, and decreases maintenance.

Sprockets are characterized by type, which indicates hub style:

Type A sprockets are flat and have no hub. They are usually mounted on flanges or hubs of the device they are driving through a series of holes that are plain or tapered.

Type B sprockets have a hub on one side, allowing the sprocket to be fitted closely to the machinery on which it is mounted. This eliminates a large overhung load on the bearings of the equipment.

Type C sprockets are extended on both sides of the plate and usually used on the driven sprocket where the pitch diameter is larger and where there is more weight to support on the shaft. Larger loads should have larger hubs.

Type D sprockets use a type A sprocket mounted on a solid or split hub. The sprocket is split and bolted to the hub for easy removal. Speed ratio can be changed by without having to remove bearings and other equipment.

Sprocket Selection Terminology

Sprocket Hub Style: A, B, and C style hub configurations are offered by many U.S. manufacturers.

Sprocket Caliper Diameter: The measurement from sprocket tooth valley to sprocket tooth valley on the opposite side. It measures the diameter of the sprocket plate without the teeth.

Sprocket Outside Diameter (OD): The measurement from sprocket tooth peak to sprocket tooth peak on the opposite side.

Maximum Bore Diameter: (B,C Styles) Maximum bore size a sprocket can be machined without compromising structural integrity.

Length Through Bore (LTB): The inside hub diameter and the length to which it was machined. The length must be able to accommodate the proper size keyway to withstand shear and torque stress.

Plain Bore: (B,C Styles) where inside diameter of the hub is machined with a standard keyway and two set screws.